5 Simple Techniques For Motorcycle Parts New Zealand Specialists

Wiki Article

Rumored Buzz on Motorcycle Parts New Zealand Specialists

Table of Contents4 Easy Facts About Motorcycle Parts New Zealand Specialists ShownNot known Factual Statements About Motorcycle Parts New Zealand Specialists Not known Factual Statements About Motorcycle Parts New Zealand Specialists The Definitive Guide to Motorcycle Parts New Zealand SpecialistsThe 5-Second Trick For Motorcycle Parts New Zealand SpecialistsThe Facts About Motorcycle Parts New Zealand Specialists Uncovered6 Simple Techniques For Motorcycle Parts New Zealand SpecialistsGet This Report on Motorcycle Parts New Zealand Specialists

Get to out to one of our specialists today.CNC machining modern technology is promptly coming to be the focal factor of several manufacturing processes around the globe as a straight outcome of its several advantages over various other methods. In addition, the markets that make motorbikes have actually obtained on board with this fad. The most ingenious firms are now creating their engine components and wheels using machining methods originally developed for motorcycle components.

You may be asking yourself why we make use of. Currently that we have your attention allow us clarify the reasoning behind this modern growth in the bike production industry.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

In addition, you have full control over the appearance of the parts, even down to the min details. Periodically, motorcyclists might decide to spruce up their ride by installing aftermarket components or customizing the bike's makeover. Once once more, computer numerical control (CNC) machining is the most sensible technique. Upgrades may be of any type and style you want.

Fascination About Motorcycle Parts New Zealand Specialists

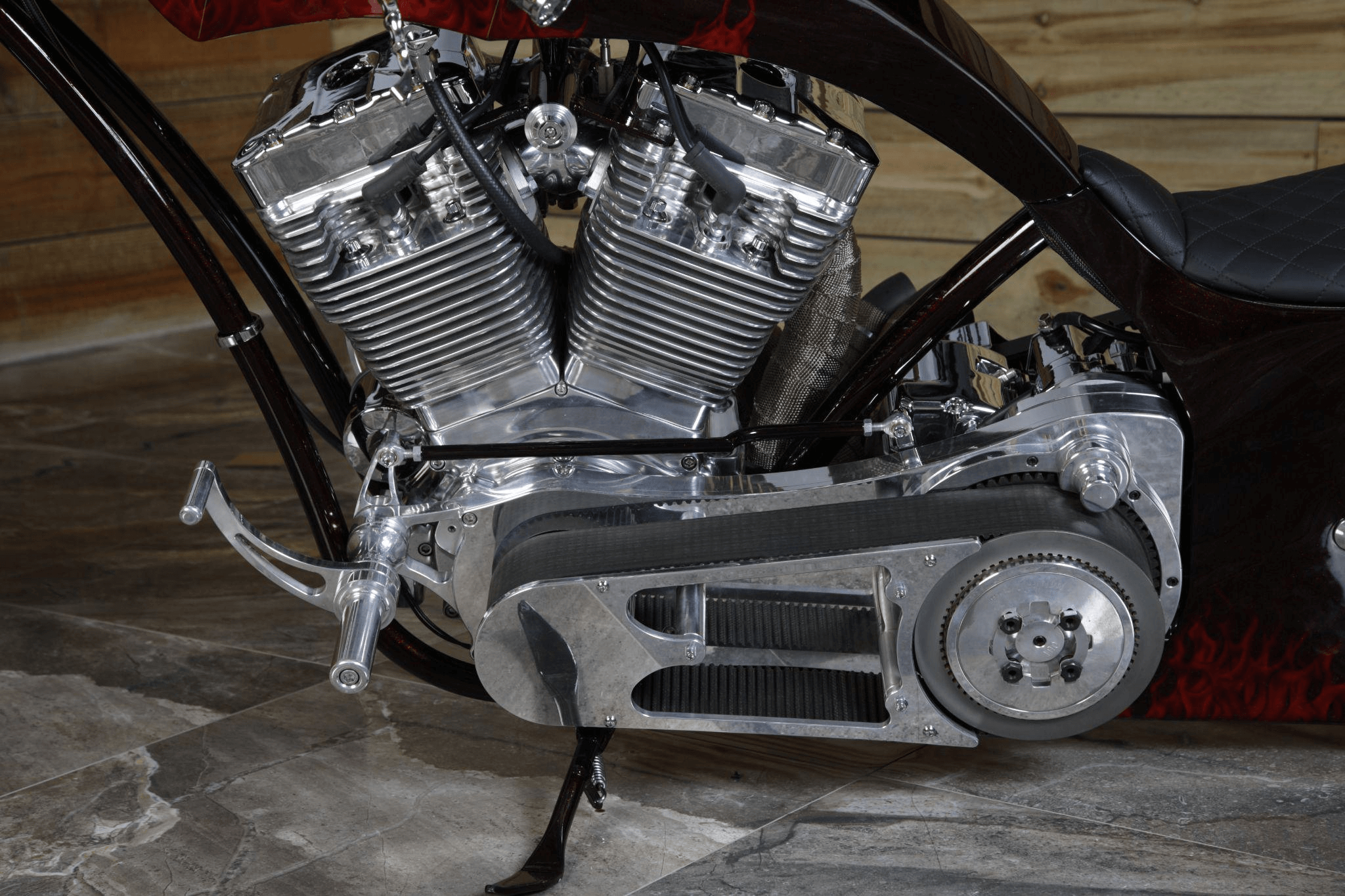

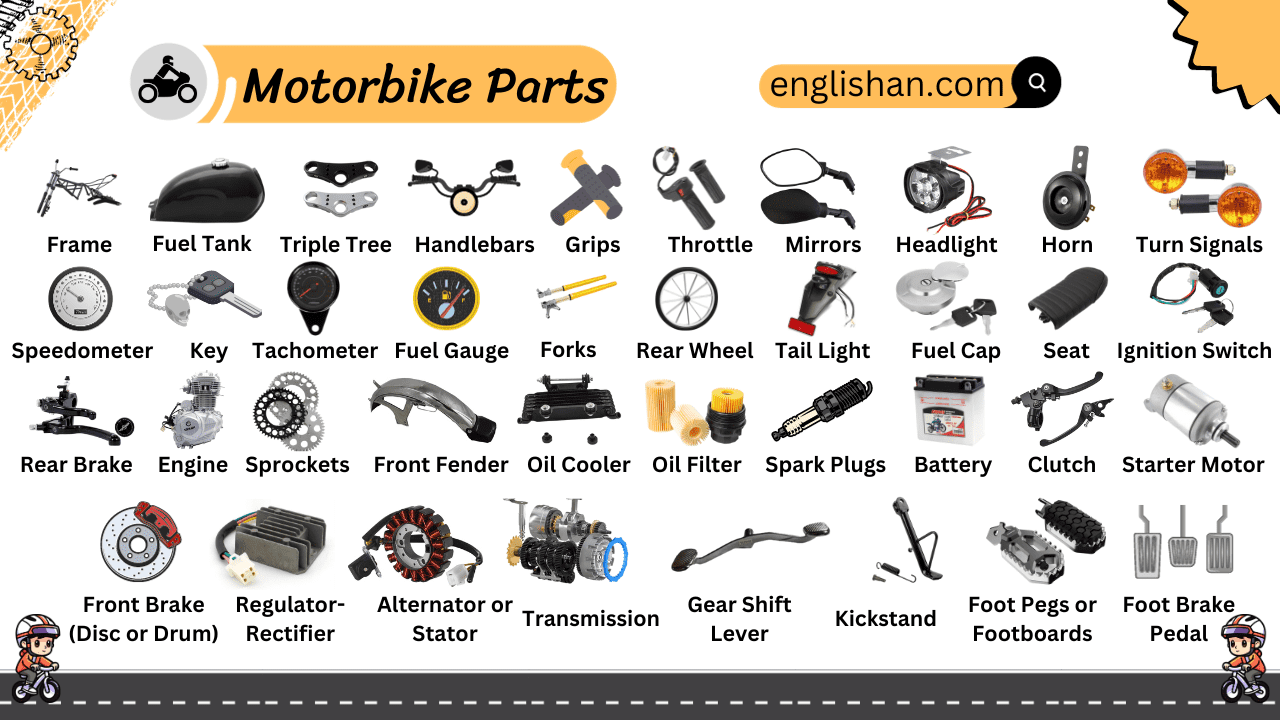

CNC machining might be used to make almost all of a motorbike's steel and plastic components. To continue, we'll review several machined components for motorbikes. In comparison to those on automobiles, wheels on motorbikes have a tendency to be extra obvious. Because of this, the bike's appearances may be improved with the suitable customization of these wheels.Milling treatments are used to acquire the desired degree of wheel customization. One more aspect of the motorcycle that may be individualized is the tires.

Not known Facts About Motorcycle Parts New Zealand Specialists

When it concerns a vehicle (or a motorbike), the most crucial element is the engine. Several individuals suggest to it as the "heart" of the automobile. On the various other hand, the camshaft, the cyndrical tube head, and the pistons tend to be complex and call for styles with a high level of precision.Use only top notch products, nonetheless, considering that these lights are vital for the safety and security of motorcyclists and other vehicle drivers or individuals on the road, specifically at night. Motorcycle headlights have 3 primary components: the light bulb, or light source, the lens, and the real estate.

Milling procedures with a flawless finish would result in the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the various other hand, is not made up of delicate materials; rather, it is built out of tough polymers that look at this now can be machined right into more intricate patterns.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Bike manufacturers typically cast these elements, however only for the production of bespoke components. Machining on 5 axes in today's world is the methods by which any kind of style form may be recognized.The success of the process is contingent on the mill cutters' capacity to compute subtle and challenging angles accurately. Pick Runsom for your customized motorcycle parts! We have the capacity to make difficult and elegant elements making your bike matchless. The majority of are crafted from light weight aluminum or steel alloys, each of which has its uses and benefits.

Here are a couple of instances of metals often used in bike part machining. Aluminum is the main material used by firms focusing on creating custom-made bike parts to produce a lot of these parts. In the past, we would construct our engines out of actors iron. On the various other hand, aluminum is rapidly coming to be the material of choice, partly as a result of the truth that it is a lot more light-weight.

Zinc describes another steel that is really light in weight and has great machining high qualities because of its high mechanical stamina. This product may be created into virtually any kind of form and keeps its measurements well. Also mission-critical components that require a high degree of precision might gain from their use.

Examine This Report about Motorcycle Parts New Zealand Specialists

One more metal that sees hefty usage in the production of CNC-customized components is magnesium. It is amongst the lightest metals that are now easily accessible and has superb machinability functions and toughness proportionate with its low weight. Among the downsides of magnesium is that its dirt might quickly ignite.

Due to its remarkable machinability and weldability, stainless steel is an alloy that is specifically appropriate for CNC processes. Along with this, they have great rust resistance and a high visual allure. Their most typical use in producing various motorcycle components is bolts, such as screws and bolts. Their low vulnerability find to oxidation and deterioration makes them ideal for this usage.

See This Report on Motorcycle Parts New Zealand Specialists

It seems that CNC turning and grating are the foundational processes. Alternative strategies exist, such as boring. Allow's explore a lot of these machining strategies comprehensive. The CNC transforming strategy is taken into consideration a subtractive manufacturing technique. On top of that, it needs maintaining bars of material, usually plastic or steel, ready and after that turning a cutting tool to eliminate areas of the product as the product is turned.

These approaches are similarly essential and create components with high precision and consistent quality. The processes aid enhance the overall high quality of the machined motorbike parts.

Everything about Motorcycle Parts New Zealand Specialists

Report this wiki page